Metal Surface Treatment Guide from an ISO 9001 Certified Precision Machining Facility

Why Surface Treatment Matters in CNC Machining

In precision manufacturing, surface finishing is not only about aesthetics — it is about performance, durability, and process control.

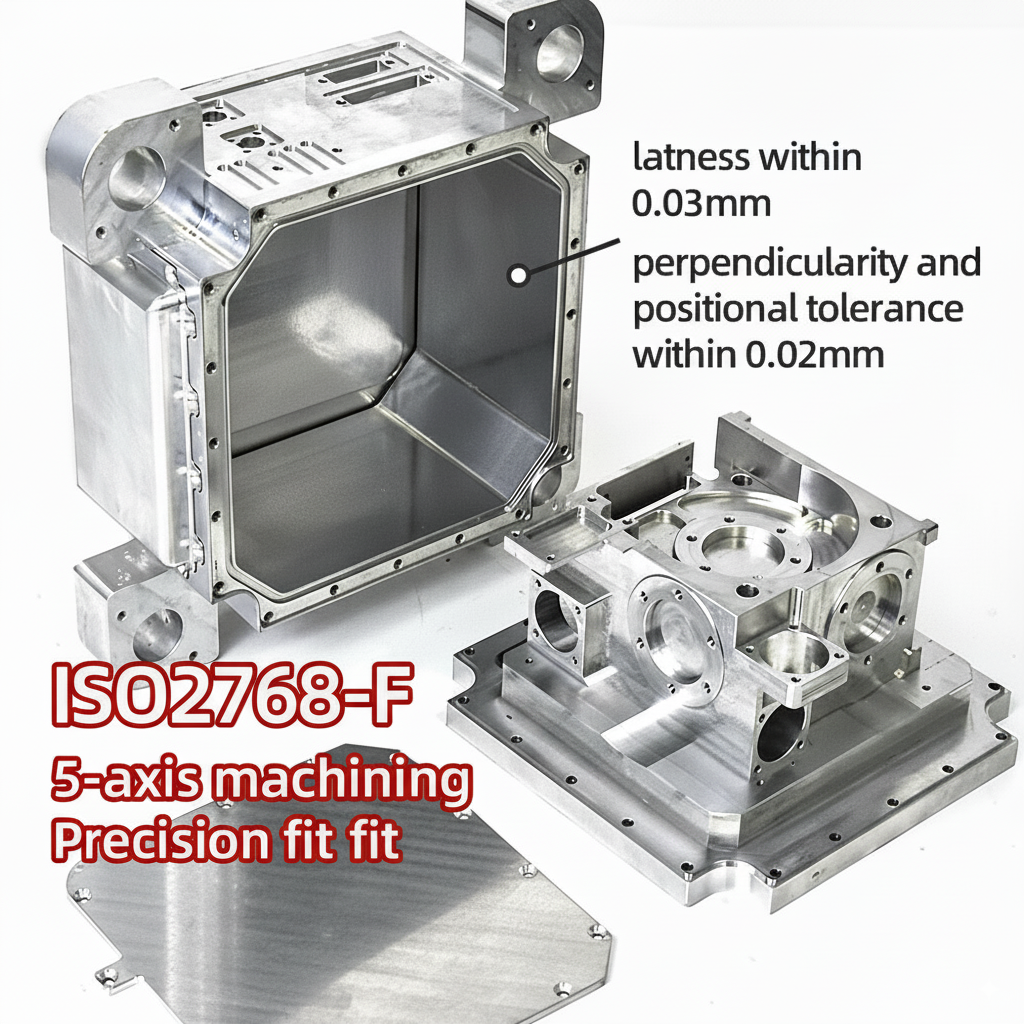

At Bergek CNC, an ISO 9001 certified facility with 5-axis machining expertise, the choice of finishing process directly affects:

Corrosion resistance – how parts perform in real environments

Durability – resistance against scratches, abrasion, and chemicals

Aesthetics – brand perception and product value

Manufacturability – consistency from prototypes to production runs

Common questions we hear: “Is anodizing enough for outdoor use?” or “Should I switch from painting to powder coating for better durability?”

The answer requires both engineering judgment and quality system assurance.

Comparison of Common Surface Treatments

| Process | Appearance | Durability | Typical Thickness | Standards | Applications | Limitations |

|---|---|---|---|---|---|---|

| Anodizing (阳极氧化) | Metallic finish, multiple colors | Excellent corrosion resistance, hardness up to ~300 HV | 5–25 μm (Type II), 25–100 μm (Type III) | ISO 7599, MIL-A-8625 | Electronics housings, aerospace components | Color consistency can vary across alloys and batches |

| Powder Coating (粉末喷涂) | Smooth, uniform, rich colors | 500–1,000 hrs salt spray (ASTM B117, lab); field performance depends on UV & wear | 60–120 μm | ISO 8130, ASTM D3359 | Automotive, appliances, enclosures | Not ideal for fine features; coating buildup possible |

| Painting (喷漆) | Flexible colors, supports patterns | 100–250 hrs salt spray typical (ASTM B117); limited scratch resistance | 15–25 μm | ASTM D3359, ISO 2409 | Prototypes, short-life consumer goods | Inconsistent in mass production, prone to chipping |

| Clear Coat (清漆保护层) | Transparent gloss, keeps natural metal | 50–150 hrs salt spray (ASTM B117, indoor use); outdoors <6 months without UV blockers | 10–20 μm | ASTM D3363 | Display parts, cosmetic panels | Limited corrosion protection; mainly aesthetic |

Engineer’s Notes

Anodizing → Excellent for 6061/5052 alloys; poor results on high-silicon die-cast aluminum (ADC12, A380).

Powder Coating → More durable than wet paint, but design must avoid coating in threads and tight clearances.

Painting → Fast and cheap, but adhesion weaker and wear resistance lower than powder coating.

Clear Coat → Serves mainly as a cosmetic sealer; should not be relied upon for corrosion-critical applications.

Always evaluate finishing options in both lab tests and real-world conditions.

Other Advanced Finishes

Plating (电镀) → Nickel/chrome plating for wear resistance; zinc plating for corrosion protection.

Passivation (钝化) → Improves stainless steel corrosion resistance by enhancing oxide stability.

Electropolishing (电解抛光) → Produces ultra-smooth surfaces for medical, semiconductor, and food-contact parts.

Real Customer Case

An automotive customer initially specified wet painting for enclosures. In lab tests: failures after ~250 hrs salt spray (ASTM B117). After switching to powder coating: passed 1,000 hrs lab test and showed significantly fewer field failures.

Instead of marketing claims, we track results through standardized testing and field performance monitoring.

FAQ: Common Engineering Questions

Q1: Is powder coating always more durable than painting?

Yes, under lab tests: powder coating typically 60–120 μm, 500–1,000 hrs salt spray; painting 15–25 μm, 100–250 hrs. Real-world performance depends on UV, abrasion, and environment.

Q2: Can all aluminum alloys be anodized?

No. 6061/5052 anodize well; high-silicon die-cast alloys yield uneven finishes.

Q3: How long does clear coat protection last?

Typically 6–12 months indoors; outdoor use without UV blockers may drop below 6 months. Specialized coatings can extend service life.

Q4: What does ISO 9001 ensure in surface finishing?

ISO 9001 does not define finishing quality itself. It ensures process consistency:

- Documented coating thickness checks

- Batch traceability & QC reports

- Periodic adhesion/hardness tests per ASTM/ISO standards

Q5: Which finishes are FDA-compliant for food or medical parts?

Electropolishing and specific passivation processes are suitable for stainless steel components, validated with FDA and ISO 13485 standards.

Bergek CNC’s Approach

Engineer-Verified DFM Reviews – Ensuring feasibility and performance.

Material & Process Guidance – Helping clients balance cost, durability, and compliance.

Consistency Control – ISO 9001 systems ensure every batch matches approved specs.

We are not just a machining vendor — we are your engineering partner for reliable manufacturing.

Final Thought

The right surface finish goes beyond looks. It defines durability, reliability, and trust.

With ISO 9001 certified quality management and 5-axis machining expertise, Bergek CNC helps clients across automotive, aerospace, medical, and consumer industries achieve consistent, reliable finishing results.

SEO Keywords:

ISO 9001 certified CNC machining, 5-axis machining, surface treatment, anodizing, powder coating, painting, clear coat, plating, passivation, electropolishing, precision sheet metal, DFM review, medical device finishing

READ MORE:

- Quality Control in 5-Axis CNC Machining

- 5-Axis CNC Machining for Customized Parts

- What Industries Need 5-Axis CNC Machining? | Expert Analysis by BERGEK

- 5-axis Machining Tolerances & Surface Finish | Engineering Guide – BERGEK ISO 9001

- ISO 9001 certified 5-axis CNC machining supplier in China

- How 5-Axis Machining Improves Aerospace Components

- What is 5-Axis CNC Machining? Engineer’s Decision Guide & ISO 9001 Certified Solutions

- Engineering Guide: How to Select the Right Metal Thickness for CNC Machining

- Short Lead Times, High Precision: Why More Manufacturers Rely on ISO 9001 CNC